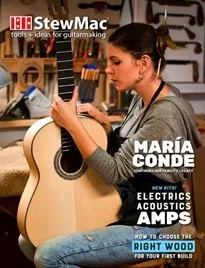

Stewart-MacDonald Guitar Catalog

Guitar maintenance and construction require a level of precision that standard household tools cannot provide. The specialized inventory found in professional catalogs serves as the foundation for high-quality instrument care. From the initial setup to complex structural repairs, having access to the correct components ensures that every adjustment enhances the playability and tonal quality of the guitar. This focus on technical excellence allows both hobbyists and professional luthiers to maintain instruments at their peak performance levels. Using precision instruments designed specifically for the unique geometry of stringed instruments prevents common errors that can occur with improvised equipment. Every measurement, from the height of a nut slot to the radius of a fretboard, demands accuracy to the thousandth of an inch.

Understanding the vast array of available hardware and tools is crucial for any successful guitar project. Whether it involves upgrading electronics for better clarity or refretting a vintage neck to restore its original feel, the selection of materials plays a pivotal role. High-grade materials and engineered tools minimize the risk of damage while maximizing the efficiency of the repair process. This exploration into professional-grade supplies demonstrates why specialized equipment is indispensable for anyone serious about the craft of lutherie. By utilizing resources that provide exact specifications and specialized functionality, technicians can ensure that every modification contributes positively to the instrument’s longevity and acoustic properties.

The Significance of Specialized Measurement Tools

In the world of guitar repair, measurement is the first step toward improvement. A significant portion of the Stewart-MacDonald Guitar Catalog is dedicated to tools that provide accurate feedback on an instrument’s current state. These tools allow a technician to diagnose issues such as neck relief, string height, and fret leveling with absolute certainty. Without these measurements, any adjustment is merely guesswork, which can lead to poor performance or even permanent damage to the wood and hardware.

Achieving Perfect String Action

The relationship between the strings and the fretboard, commonly referred to as string action, is the most critical factor in how a guitar feels to the player. Tools like the string action gauge provide a quick and reliable way to measure the distance between the top of the fret and the bottom of the string. This measurement is vital for ensuring that the guitar is easy to play without causing excessive fret buzz. By using a gauge that provides measurements in both inches and millimeters, a builder can achieve a setup that meets the specific preferences of any musician. Precision at this stage ensures that the instrument responds predictably across the entire length of the neck.

Furthermore, understring radius gauges are essential for matching the curvature of the bridge saddles to the curvature of the fretboard. When the bridge radius does not match the neck radius, the middle strings may sit too high or the outer strings may sit too low, leading to an inconsistent playing experience. By checking the radius at both the nut and the bridge, a technician can create a uniform feel that allows for smooth transitions between chords and lead lines. This level of detail is what separates a standard setup from a professional-grade optimization.

Maintaining Neck Relief and Straightness

A guitar neck is under constant tension from the strings, and the truss rod serves as the counter-force to maintain the proper amount of bow, or relief. To measure this accurately, a notched straightedge is used to sit directly on the wood of the fretboard, bypassing the frets themselves. This allows the technician to see the actual straightness of the neck without being misled by worn or uneven frets. Once the neck is confirmed to be straight, a feeler gauge can be used to measure the specific amount of relief required for the player’s style. These specialized tools ensure that the truss rod is adjusted only as much as necessary, preserving the structural integrity of the neck over time.

Essential Hardware for Structural Integrity

Beyond tools, the catalog provides a massive selection of hardware that serves as the mechanical backbone of the guitar. High-quality bridges, tuning machines, and nuts are not just aesthetic choices; they are functional components that dictate how well an instrument stays in tune and how efficiently energy is transferred from the strings to the body. Upgrading these components is one of the most effective ways to improve a budget-friendly instrument or restore a vintage one to its former glory.

Tuning Machine Precision

Tuning stability is often the most significant concern for performing musicians. High-ratio tuning machines allow for much finer adjustments, making it easier to reach the exact pitch and stay there. The internal gears of professional-grade tuners are machined to tight tolerances to eliminate backlash, which is the movement felt when the tuner knob is turned but the post does not move. By installing tuners with a 16:1 or 18:1 gear ratio, a player gains much more control over their tuning process. Additionally, locking tuners provide a mechanical solution to string slippage, significantly reducing the time it takes to change strings while improving stability during heavy use of a tremolo system.

Bridge and Saddle Customization

The bridge is the primary contact point for the strings on the body of the guitar, making it a major factor in the instrument’s intonation and tone. Replacement bridges made from high-density materials like brass or steel can increase the sustain of a guitar by reducing the amount of energy lost through vibration. For acoustic guitars, the bridge pins and saddle materials, such as bone or high-tech composites, can drastically change the brightness and clarity of the sound. The catalog offers various options to suit different tonal goals, allowing for a customized approach to every build. Adjusting the individual saddles for intonation ensures that the guitar plays in tune at every fret, a necessity for professional recording and performance.

Advanced Electronics for Sonic Clarity

For electric guitars, the internal circuitry is just as important as the wood itself. The Stewart-MacDonald Guitar Catalog includes a wide range of pickups, potentiometers, and capacitors that allow for total control over the electronic signal. Using high-quality electronics reduces unwanted noise and provides a more musical response when the volume or tone knobs are adjusted. This is particularly important for players who rely on their guitar’s controls to shape their sound during a performance.

- High-output pickups for increased drive and sustain.

- Vintage-voiced pickups for classic clarity and warmth.

- Low-friction potentiometers for smooth volume swells.

- Copper shielding tape to eliminate electromagnetic interference.

- Pre-wired harnesses for easy installation and reliable connections.

Properly shielding the internal cavities of an electric guitar is a step often overlooked in mass production. By applying conductive copper tape or shielding paint, a technician can create a Faraday cage that protects the signal from outside interference. This results in a much quieter instrument, especially when using high-gain amplifiers. Furthermore, the use of high-quality switches and jacks ensures that the guitar remains reliable on stage, preventing the common pops and crackles associated with inferior components.

Professional Finishing and Restoration Supplies

The final aesthetic of a guitar is determined by its finish, and the catalog provides the professional-grade supplies needed to achieve a factory-quality look. This includes everything from traditional nitrocellulose lacquers to modern water-based finishes and the abrasives required to level and buff them. Finishing is a labor-intensive process that requires patience and the right materials to ensure a durable and beautiful result.

Polishing compounds and buffing wheels are used to bring a cured finish to a high-gloss shine. For older instruments, specialized cleaners and restorers can remove years of grime without damaging the original finish. These products are formulated to be safe for use on delicate instrument woods, ensuring that the cleaning process does not lead to cracking or discoloration. By following a systematic approach to finishing and maintenance, a builder can protect the instrument from environmental factors like humidity and temperature changes, which are the primary causes of wood movement and finish checking.

Whether the goal is to build a brand-new instrument from scratch or to perform a simple setup on a favorite guitar, the tools and parts found in a professional resource are essential. The precision and quality offered by these components allow for a level of craftsmanship that honors the instrument’s potential. For those looking to explore the full range of possibilities for their next project, consulting the Stewart-MacDonald Guitar Catalog provides the necessary roadmap for success.